Project Description

Visit our website with a bigger device for more information

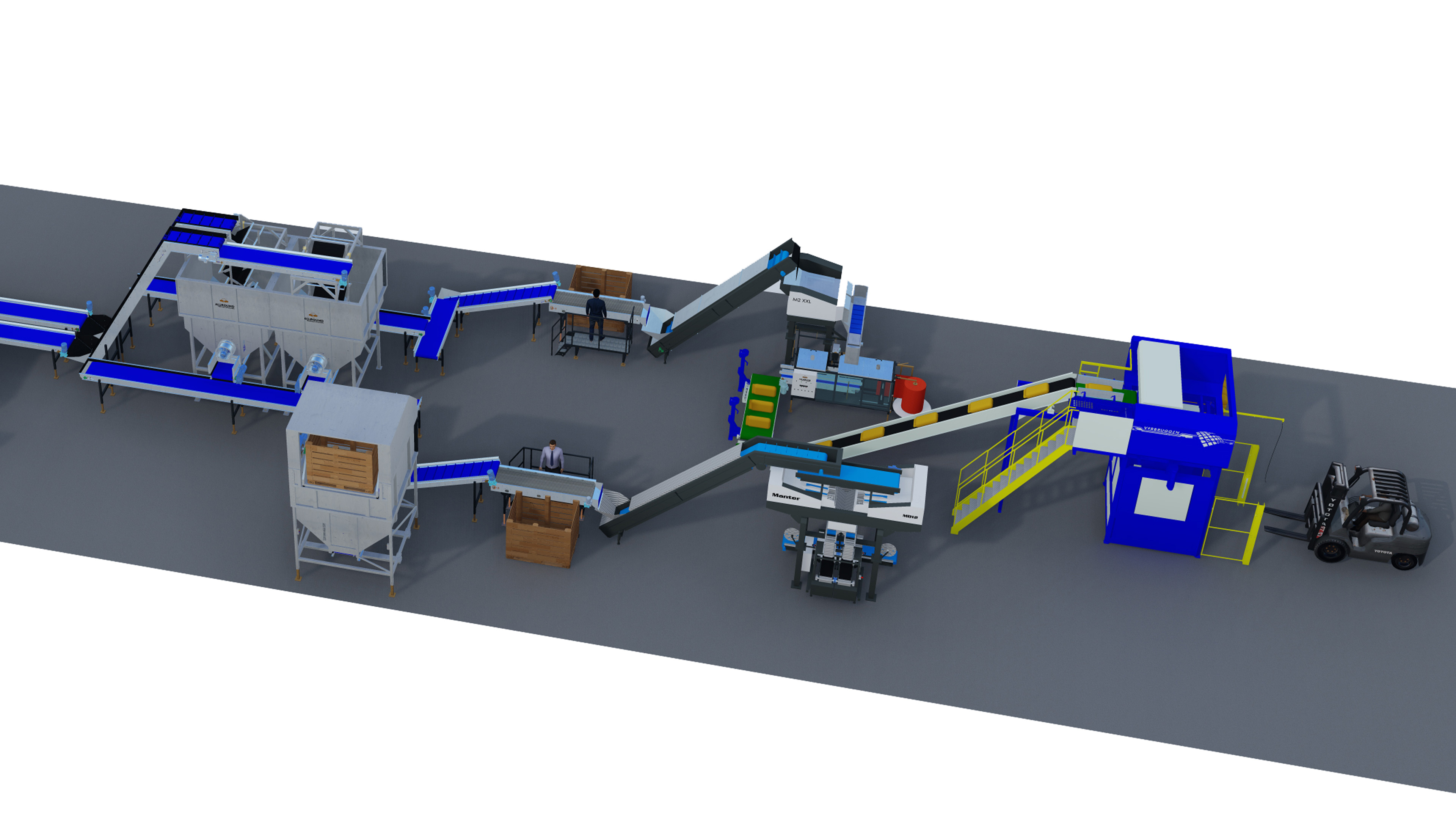

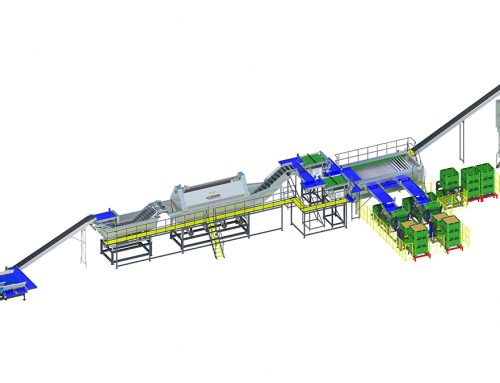

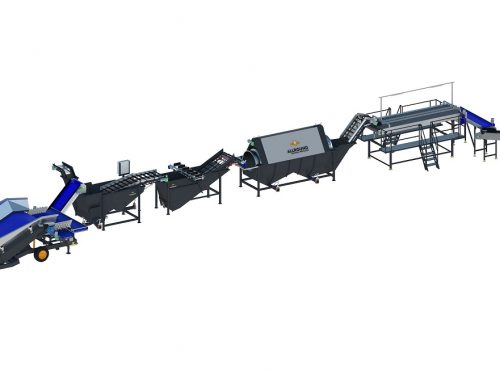

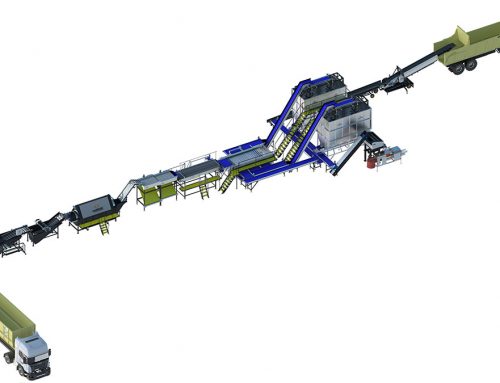

POTATO PROCESSING LINE 450 SERIES

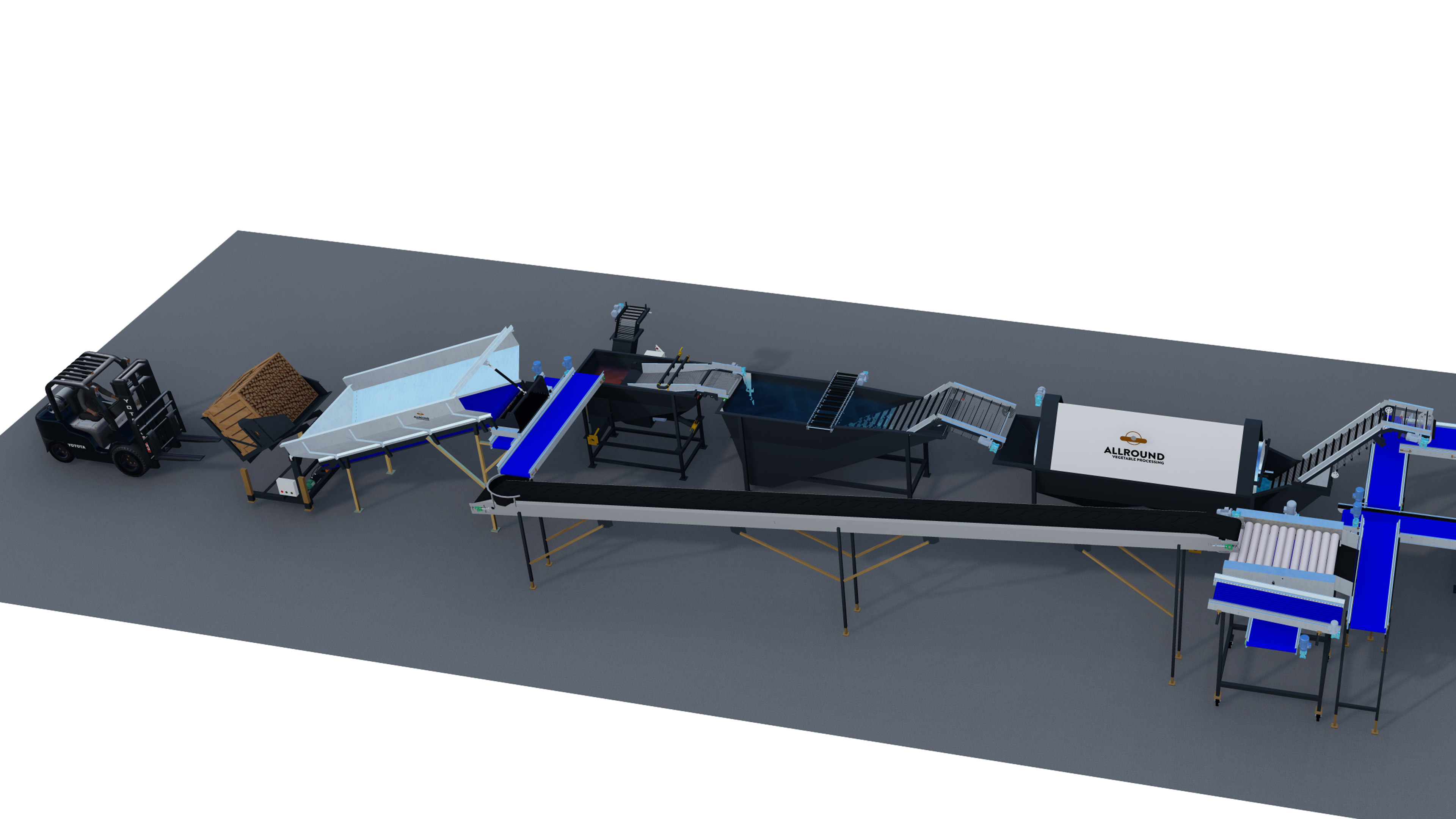

Washing area contains a Destoner when there is a lot of dirt coming along with the produce, destoners are the ideal machines.

Also a Skin sperator that is designed to remove floating pieces from the produce. This could be for example loose pieces of skin or branches and leafs.

The washing drum of the Washing machine is designed to agitate produce in the machine. In combination with water, this process gives an optimal cleaning result.

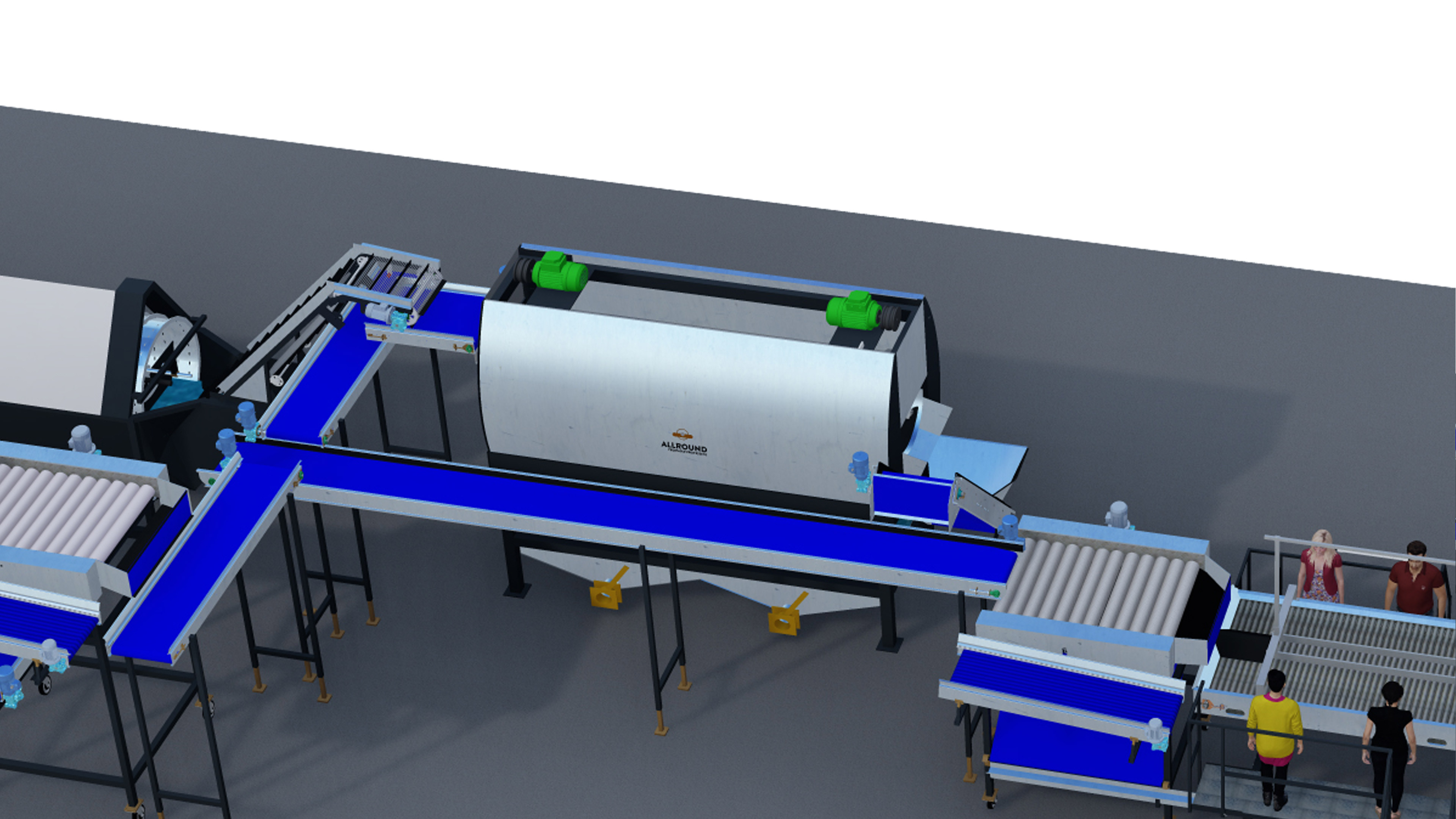

Polishers are designed to wash and polish produce. This process is commonly used at companies that want to give their produce a ‘premium’ look and feel. Furthermore, a lot of irregularities in the product will be polished away by this machine, and this process increases the shelf life of produce as well.

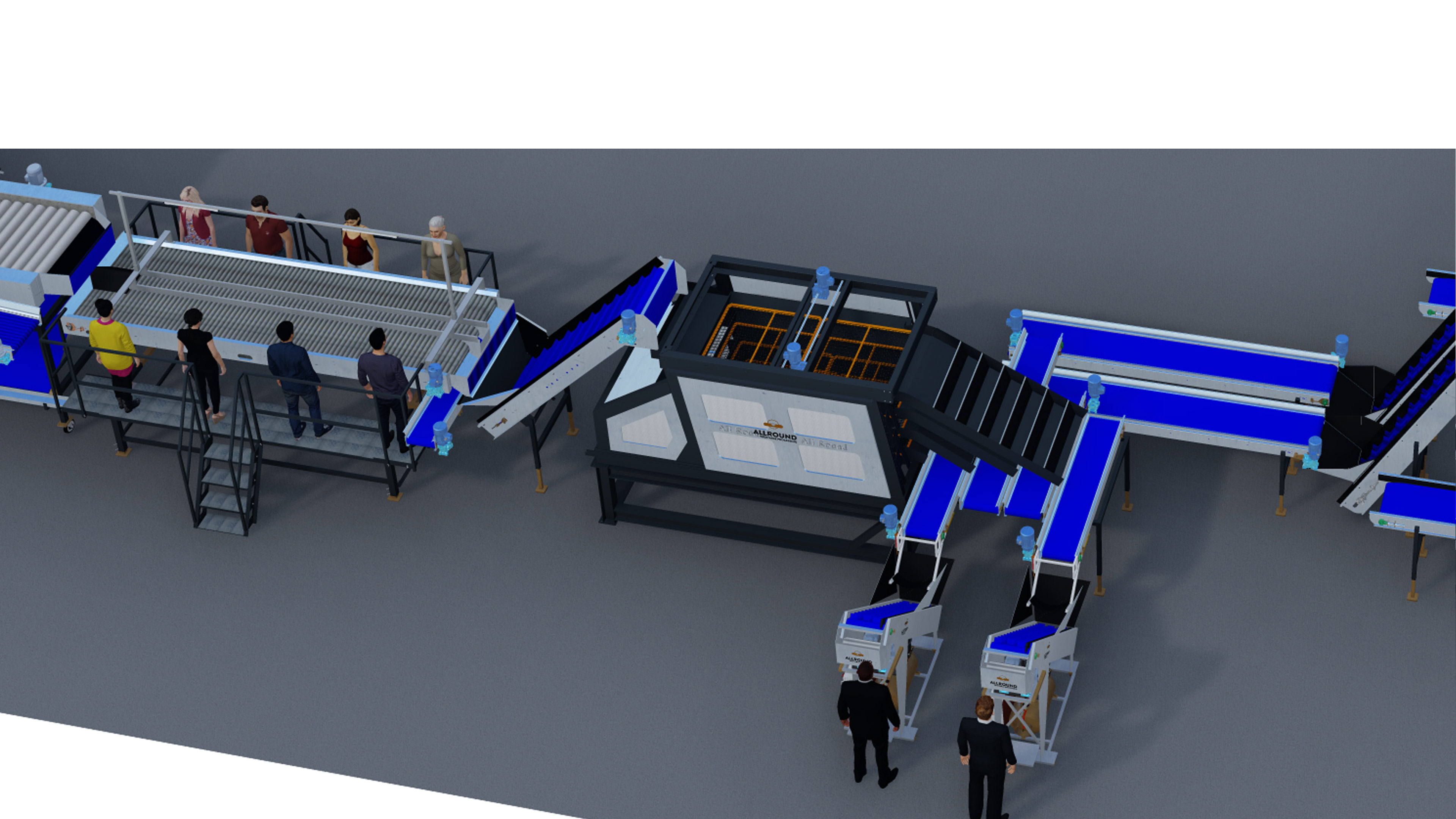

The Allround Shake grader is designed to grade potatoes according to their square size. The potatoes are fed to the top of the machine on to the top sieve. The sieves in the machine shake in sequential frequencies, which causes the potatoes to move along on the sieves.

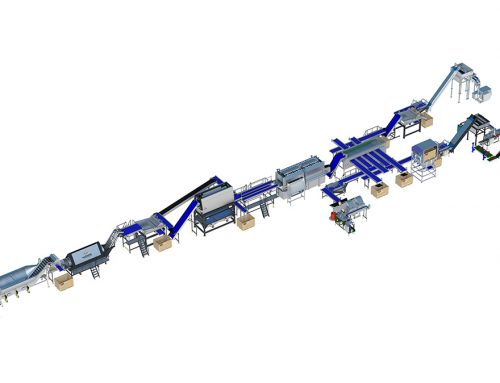

Machine

1. Box tipper

2. Hopper

3. Finger roller set

4. Waste belt

5. Product belt

6. Destoner

7. Skin separator

8. Washing machine

9. Infeed belt

10. Product belt

11. Transport belt

12. Potato brush

13. Bypass belt

14. Product belt

15. Polisher

16. Elevator

17. Transport belt

18. Potato dryer

19. Bypass belt

20. Roller inspection table

21. Waste belt

22. Elevator

23. Shake grader

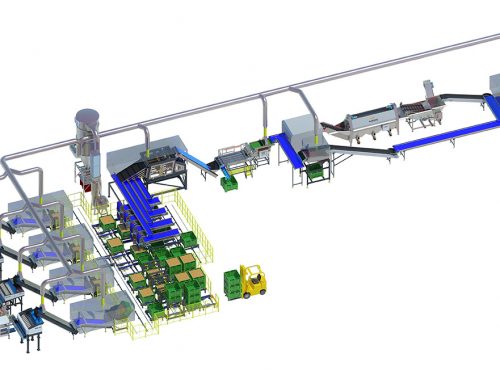

24. Automatic weighing machine

25. Product belt

26. Swan neck Elevator

27. Product belt

28. Swan neck Elevator

29. Storage bunker

30. Product belt with divertor

31. Product belt

32. Product belt

33. Storage cum box tipper

34. Cleat belt

35. Roller inspection table

36. Elevator

37. Multihead weigher

38. Rollstock bagger

39. Palletizer

40. Stand alone wrapping machine

41. Swan neck elevator

42. Multihead weigher

43. Double wicket Bagger

Type

Z-180

B 160-500

V 160-5

TB 450-60

TB 400-60

D 110

SK 160

U 450

TB 100-100

TB 300-60

TCC 1375-80

BR 120-15

TB 250-60

TB 325-60

TD 300-14

EL 300-60

TC 700-80

DR 140-17

TB 300-80

RI 120-500

TB 250-40

EL 350-90

SG 120-5

AW50-2

TB 350-60

ELK 600-100-60

TB 300-60

ELK 625-100-60

SH 25-25-10

TB 450-60

TC 550-60

TB 250-60

SHB 160

TB 400-60

RI 60-250

EL 500-60

M8

RSB-M

VPM-7

—

ELK 500-200-60

MD12

Brand

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

MANTER

MANTER

VERBRUGGEN

ALLROUND

ALLROUND

MANTER

MANTER

2D Drawings with machinery list